Products List

Contact Us

Address:Chajiawan, Jiaoxi Town, Changzhou ,Jiang Su,China

Contacter:Mr Wu

Phone:13951217139

Tel:0519-88906078 / 0519-88909287

Fax:0519-88906038

Siteurl:www.gqdry.com

Email:why681011@163.com

Other equipment series

High efficiency rotary film evaporator

Detailed description

Product Overview:

Our company has been manufacturing such equipment for many years, and has accumulated rich experience in manufacturing and use. For a long time, closely combined with the actual production of customers and market demand, in order to meet the process requirements of users, choose a reasonable and appropriate structure, to ensure superior and reliable manufacturing quality, in the tooling equipment, testing means and product design and other aspects of continuous improvement and increasingly perfect, has made remarkable achievements, technical level and product quality in the domestic level.

Equipment features:

Rotary film evaporator has the following unique advantages, which can not be compared with conventional film evaporator:

1 Minimal pressure loss

In the high efficiency rotary film evaporator, the material flow and the secondary evaporation steam flow are two independent channels: the material is falling along the inner wall of the evaporation cylinder (forced film formation); The secondary steam evaporating from the evaporation surface leaves the evaporator almost unhindered from the space in the center of the cylinder, so the pressure loss (or drag drop) is minimal.

2 It can operate under true vacuum conditions

It is precisely because the resistance of the secondary vapor from the evaporation surface to the condenser is very small, so that the evaporation surface of the entire evaporation cylinder body wall maintains a high vacuum degree (up to -750mmHg), almost equal to the vacuum degree of the vacuum system outlet, due to the improvement of the vacuum degree, effectively reduce the boiling point of the material being treated.

3. High heat transfer coefficient, high evaporation intensity

The decrease of boiling point increases the temperature difference with the heat medium. The turbulent liquid film reduces the thermal resistance; At the same time, the coking and scaling of the material on the wall are inhibited, and the heat transfer coefficient of the evaporation cylinder wall is improved. Therefore, the heat transfer coefficient of the efficient rotary film evaporator can be as high as 8000KJ/h.m2oC, so its evaporation intensity is very high.

4 Low temperature evaporation

Because the evaporation cylinder can maintain a high degree of vacuum, the boiling point of the material to be treated is greatly reduced, so it is particularly suitable for low temperature evaporation of heat-sensitive materials.

5 The overflow time is short

The flow time of the material in the evaporator is very short, about 10 seconds; For the commonly used movable scraper, the end face of the scraper material has a channeling groove, its bevel Angle is usually 45oC, change the Angle of the bevel Angle, can change the flow time of the material, the material in the scraper scraping, spiral down to leave the evaporation section. Shorten the flow time, effectively prevent the product in the evaporation process decomposition, polymerization or deterioration.

6 Low grade steam can be used

Steam is a commonly used thermal medium, due to the reduction of the boiling point of the material, under the condition of ensuring the same △t, the temperature of the heating medium can be reduced, and the use of low-grade steam is conducive to the comprehensive utilization of energy.

7 Strong adaptability, easy to operate

The unique structural design enables the product to handle some materials with high viscosity, particles, heat sensitivity and easy crystallization that are difficult to be handled by conventional evaporators.

The rotary film evaporator has the advantages of high operating flexibility, stable operating condition, small maintenance workload and convenient maintenance.

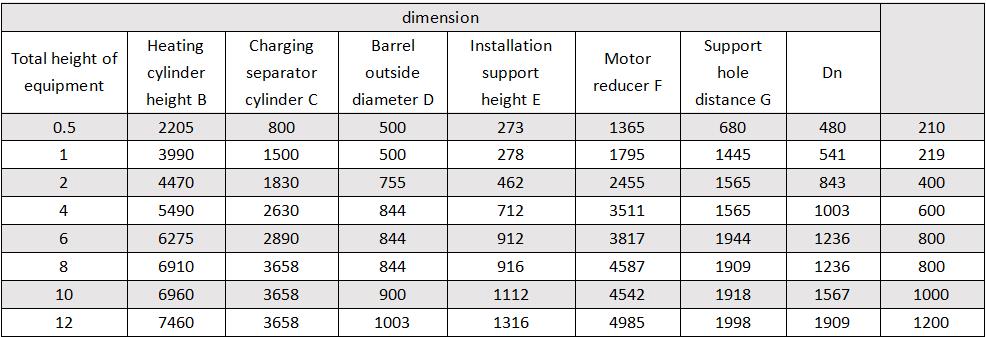

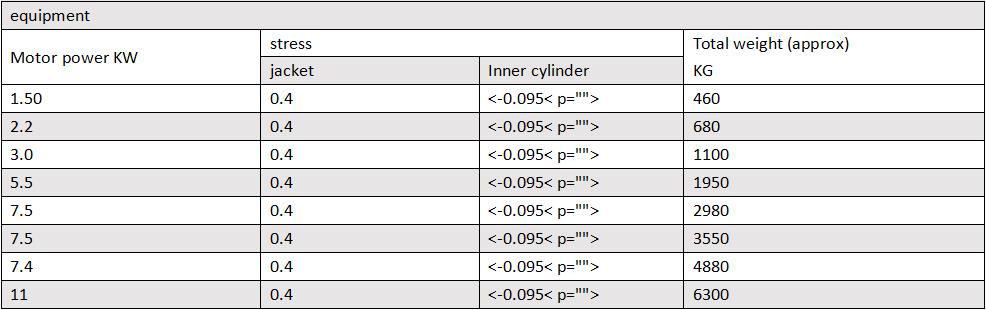

Technical parameters:

Note:

1. The above dimensions and the actual equipment may change slightly for reference, and the drawings provided by our company shall prevail after ordering;

2. The weight D indicates the outer diameter of the jacket, and Dn indicates the inner diameter of the evaporation cylinder;

3. Jacket pressure: generally according to 0.4MPa steam design, can also be designed according to user requirements, when using heat transfer oil, can also be designed;

4. Vacuum degree of evaporation inner cylinder: generally -0.09MPa(about -680mmHg), but also according to user needs, up to -0.095MPa(about -20mmHg) and -0.0986Mpa(about -750mmHg));

5. Main cylinder (the part in contact with the material) and jacket material: according to the user and actual needs, carbon steel,SUS304,316L,316Ti or titanium materials;

6. Total weight of equipment: does not include material weight.

中文

中文 英文

英文